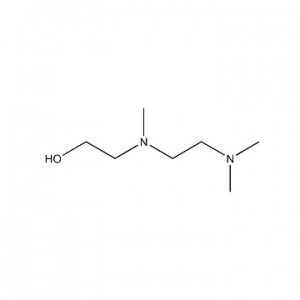

2-((2-(dimethylamino)ethyl)methylamino)-ethanol Cas# 2122-32-0(TMAEEA)

I-MOFANCAT T iyi-catalyst ephendulayo engakhiphi ukungcola ene-hydroxylgroup. Ikhuthaza ukusabela kwe-urea (isocyanate - amanzi). Ngenxa yeqembu layo le-hydroxyl ephendulayo, isabela kalula kwi-matrix ye-polymer. Inikeza iphrofayili yokusabela ebushelelezi. Ine-fogging ephansi kanye ne-PVC ephansi yokudaya. Ingasetshenziswa ezinhlelweni ze-polyurethane eziguquguqukayo neziqinile lapho kudingeka khona iphrofayili yokusabela ebushelelezi.

I-MOFANCAT T isetshenziselwa ukuvikela i-spray foam, i-slabstock eguquguqukayo, i-packaging foam, amaphaneli ezinsimbi zezimoto kanye nezinye izindawo lapho kudingeka khona i-catalyst enikeza iphunga eliphansi noma ukusebenza okungafuduki.

| Ukubonakala: | uketshezi olungenambala kuya kophuzi olukhanyayo | |

| inani le-hydroxyl (mgKOH/g) | 387 | |

| Ubuningi obuhlobene (g/mL ku-25 °C): | 0.904 | |

| Ukuthamba (@25 ℃ mPa.s) | 5~7 | |

| Indawo Yokubila (°C) | 207 | |

| Indawo Yokuqandisa (°C) | <-20 | |

| ingcindezi yomusi (Pa,20 ℃) | 100 | |

| Iphoyinti Lokukhanya (°C) | 88 | |

| Ukubukeka | uketshezi olungenambala noma oluphuzi olukhanyayo |

| Ubumsulwa % | 98 Min. |

| Okuqukethwe kwamanzi % | 0.5 Ubuningi. |

170 kg / isigubhu noma ngokwezidingo zamakhasimende.

H314: Kubangela ukusha okukhulu kwesikhumba kanye nomonakalo wamehlo.

H318: Kubangela ukulimala okukhulu kwamehlo.

Ama-Pictogram

| Igama lesiginali | Ingozi |

| Inombolo ye-UN | 2735 |

| Ikilasi | 8 |

| Igama lokuthumela elifanele kanye nencazelo | Ama-Amine, uketshezi, okubolayo, ama-nos |

| Igama lekhemikhali | i-ethanol engu-2-[[2-(dimethylamino)ethyl]methylamino] |

Iseluleko ngokuphathwa okuphephile

Ungaphefumuli umusi/uthuli.

Gwema ukuthintana nesikhumba namehlo.

Ukubhema, ukudla nokuphuza kufanele kuvinjelwe endaweni esetshenziswayo.

Ukuze ugweme ukuchitheka ngesikhathi sokuphatha, gcina ibhodlela kuthreyi yensimbi.

Lahla amanzi okuhlanza ngokuhambisana nemithetho yendawo neyezwe.

Iseluleko ngokuvikela umlilo nokuqhuma

Izindlela ezijwayelekile zokuvikela umlilo.

Izindlela zokuhlanzeka

Uma usebenzisa ungadli noma uphuze. Uma usebenzisa ungabhemi.

Geza izandla ngaphambi kokuphumula kanye nasekupheleni kosuku lomsebenzi.

Izidingo zezindawo zokugcina kanye nezitsha

Gcina isitsha sivalwe kahle endaweni eyomile futhi enomoya omuhle. Landela izinyathelo zokuphepha ezilebula. Gcina ezitsheni ezilebula kahle.

Ulwazi olwengeziwe mayelana nokuzinza kwesitoreji

Izinzile ngaphansi kwezimo ezijwayelekile.

![1, 3, 5-tris [3-(dimethylamino) propyl] hexahydro-s-triazine Cas#15875-13-5](https://cdn.globalso.com/mofanpu/MOFAN-41-300x300.jpg)